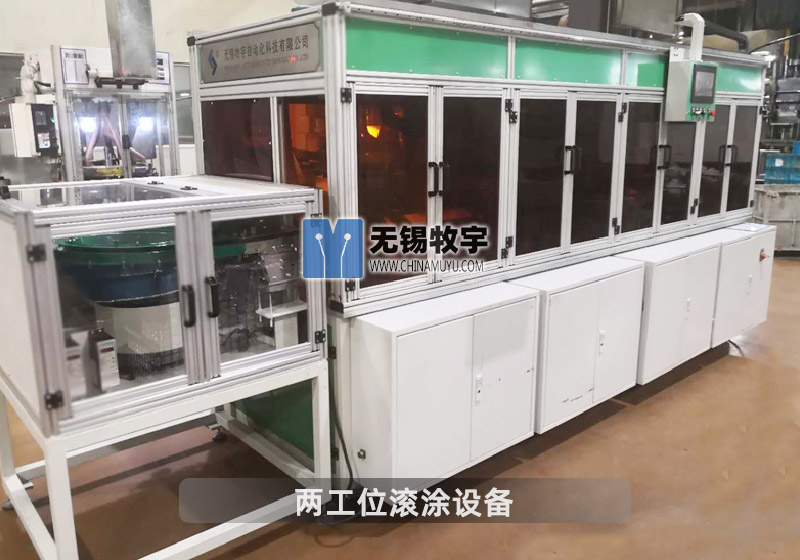

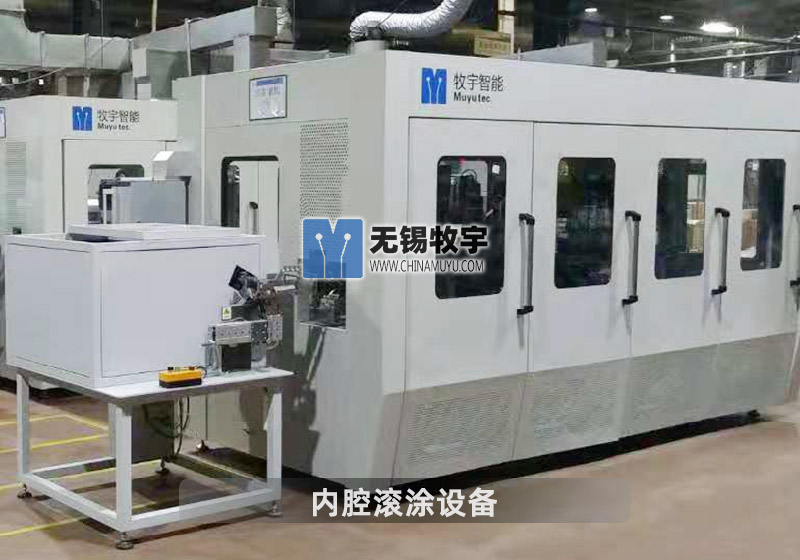

Adhesive roll coating equipment

It is an automatic equipment specially developed for round regular parts, which is suitable for gluing work pieces inside round pipes.

| PARTS DISPLAY | KEY POINTS | SUMMARY | TECHNICAL DATA | APPLICATION |

|

1.The heating temperature is ± 2 ℃; |

2.The total film thickness was ± 3 μ M; |

|

3.The primer coating was detected by CCD; |

4.he surface glue coating was detected by CCD; |

|

5.Unqualified products shall be discharged immediately; |

6.Real time monitoring of coating stock; |

|

7.Real time monitoring of coating mixing; |

8.Real time monitoring of exhaust gas concentration; |

|

9.Safety protection of sports mechanism; |

10.Compressed air pressure monitoring; |

|

11.Measurement of qualified products |

|

High degree of automation: workpiece feeding, gluing, detection, drying, blanking are fully automatic, including picking out the unqualified products, one person can control multiple equipment.

Save energy consumption and raw materials: compared with the manual brushing efficiency increased by 8 times, compared with the spraying process, the raw materials (glue) were saved by 40%. Energy consumption is 40% less than glue spraying equipment, which is more environmentally friendly.

Stable quality: using image detection and conductivity detection to ensure that the unqualified products flow into the next process. The qualified rate of products is more than 99%.

This product is used for the continuous production of automobile parts / household appliances / electronic products and other mass products, with the best effect, convenient operation, less maintenance points and superior automation performance.

Total power: 20kW, normal operation power: 10-15kw

|

Equipment name |

Automatic roller coating machine for inner wall of tube |

Roll coating |

Chemlok/Rohm & Haas |

|

Scope of application |

DN37~100*L25~100mm |

Workpiece material |

Carbon steel / aluminum alloy / PA, etc |

|

Beat time |

4~8s/pcs |

Feeding mode |

Once every 30 ~ 60min |

|

Workpiece heating |

Hot air preheating / primer drying / topcoat 1 drying / topcoat 2 drying |

||

|

Technological process |

Automatic feeding → preheating → primer → drying → detection → topcoat 1 → drying → topcoat 2 → drying → detection → discharge |

||

|

Floor size |

5600*3600*2600mm |

Equipment weight |

About 3.6T |