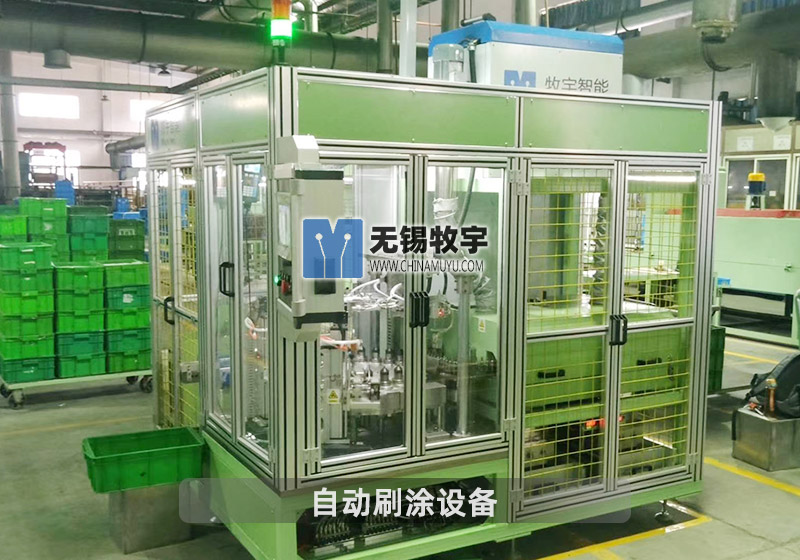

Adhesive brushing equipment

It is an automatic equipment specially developed for special-shaped and irregular parts.

| PARTS DISPLAY | KEY POINTS | SUMMARY | TECHNICAL DATA | APPLICATION |

|

1.The heating temperature is ± 2 ℃; |

2.The total film thickness was ± 3 μ M; |

|

3.The primer coating was detected by CCD; |

4.The surface glue coating was detected by CCD; |

|

5.nqualified products shall be discharged immediately; |

6.Real time monitoring of coating stock; |

|

7.Real time monitoring of coating mixing; |

8.Real time monitoring of exhaust gas concentration; |

|

9.Safety protection of sports mechanism; |

10.Compressed air pressure monitoring; |

|

11.Measurement of qualified products; |

|

High degree of automation: glue supply, track, detection, drying, temperature control are fully automatic.

This product is used for continuous production of large quantities of local gluing products such as automobile parts / household appliances / electronic products, with the best effect, convenient operation, less maintenance points and superior automation performance.

The total power of the equipment is 20kW, and the normal operation power is 8-12kw

|

Equipment name |

Automatic brushing machine |

Roll coating |

Chemlok/Rohm & Haas |

|

Scope of application |

∮6~300*L10~200mm |

Workpiece material |

Carbon steel / aluminum alloy / PA, etc |

|

Beat time |

6~15s/Pcs |

Feeding mode |

Automatic / manual |

|

Workpiece heating |

Hot air preheating / primer drying / topcoat 1 drying / topcoat 2 drying (optional) |

||

|

Technological process |

Feeding → preheating → primer → drying → topcoat 1 → drying → topcoat 2 → drying → discharging |

||

|

Floor size |

3~15㎡ |

Equipment weight |

1~5T |