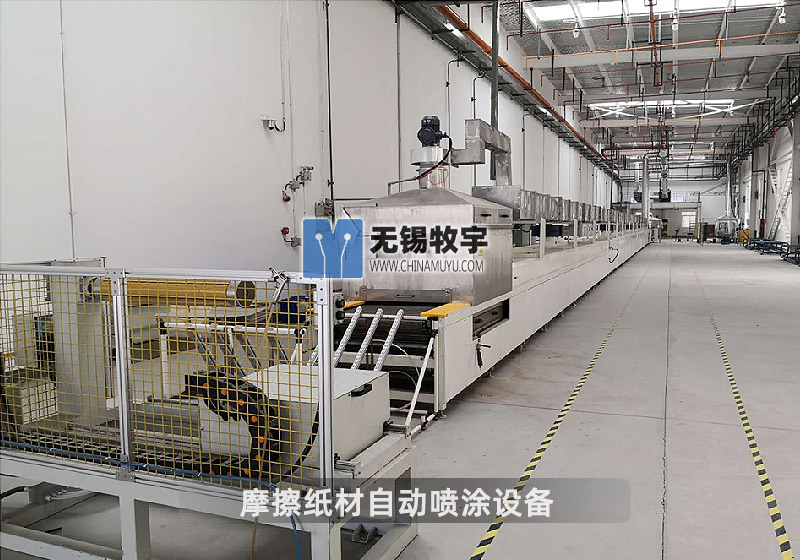

Adhesive spraying equipment

This equipment is independent research and development, with a number of national patents. It is suitable for local gluing workpieces.

| PARTS DISPLAY | KEY POINTS | SUMMARY | TECHNICAL DATA | APPLICATION |

|

1.The heating temperature is ± 2 ℃; |

2.The total film thickness was ± 3 μ M; |

|

3.The primer coating was detected by CCD; |

4.The surface glue coating was detected by CCD; |

|

5.Unqualified products shall be discharged immediately; |

6.Real time monitoring of coating stock; |

|

7.Real time monitoring of coating mixing; |

8.Real time monitoring of exhaust gas concentration; |

|

9.Safety protection of sports mechanism; |

10.Workpiece speed monitoring; |

|

11.Spray gun running speed monitoring; |

12.Compressed air pressure monitoring; |

|

13.Measurement of qualified products; |

|

This equipment is independent research and development, with a number of national patents. It is suitable for local gluing workpieces. It is an automatic equipment specially developed for special-shaped irregular parts. The equipment fully embodies the advantages of safety and environmental protection, energy saving, floor area saving, beautiful and practical, stable operation, convenient and safe, easy maintenance and so on.

High degree of automation: glue supply, glue spraying and drying are all automatic, suitable for one or more people to operate.

Save energy consumption and raw materials: compared with the same period of last year, the manual brushing efficiency is high and the process is stable. This product has the best continuous production effect, convenient operation, less maintenance points and superior automation performance for medium and batch products such as automobile parts / household appliances / electronic products.

The total power of the equipment is 30kW, and the normal operation power is 15-20kw

|

Equipment name |

Automatic spraying machine for special shaped parts |

Roll coating |

Chemlok/Rohm & Haas |

||

|

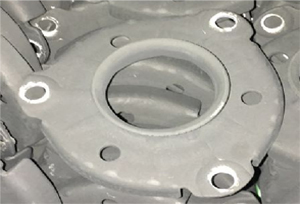

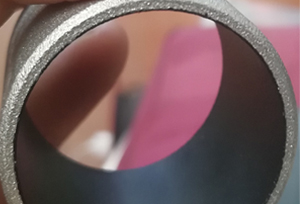

Scope of application |

Outer pipe ≥ DN 16 ~ 260; outer pipe ≥ DN 8; height ≥ 300 mm |

Workpiece material |

Carbon steel / aluminum alloy / PA, etc |

||

|

Beat time |

3 ~ 50s / group (≤ 5kg) |

Loading / unloading mode |

Automatic / manual |

||

|

Workpiece heating |

Hot air preheating / primer drying / top coating drying |

||||

|

technological process |

Feeding → preheating → bottom spraying → drying → surface spraying → drying → discharging |

||||

|

Floor size |

2800x3000x3200 |

Equipment weight |

3T |

||